ASC International: Unlocking Precision in PCB and Solder Inspection Automation

TL;DR

ASC International, a global leader in electronics inspection technology, empowers manufacturers with cutting-edge solutions for PCB and solder inspection. Their automated systems leverage advanced technologies to enhance efficiency, accuracy, and quality control in electronics manufacturing.

About ASC International

Founded in 1989, ASC International has revolutionized the PCB inspection industry with its innovative solutions. Boasting a global presence, ASC provides a comprehensive suite of products and services that address the most pressing inspection challenges.

Deciphering PCB Inspection

PCB inspection ensures that printed circuit boards (PCBs) meet stringent design specifications. Automated Optical Inspection (AOI) and X-ray inspection methods identify defects that may compromise the board’s functionality. Accurate PCB inspection is crucial to prevent costly errors and ensure product reliability.

Evolving Solder Inspection Techniques

Solder inspection involves examining solder joints for defects that can cause electrical shorts or circuit failures. Advances in technology have enabled more precise and efficient solder inspection processes.

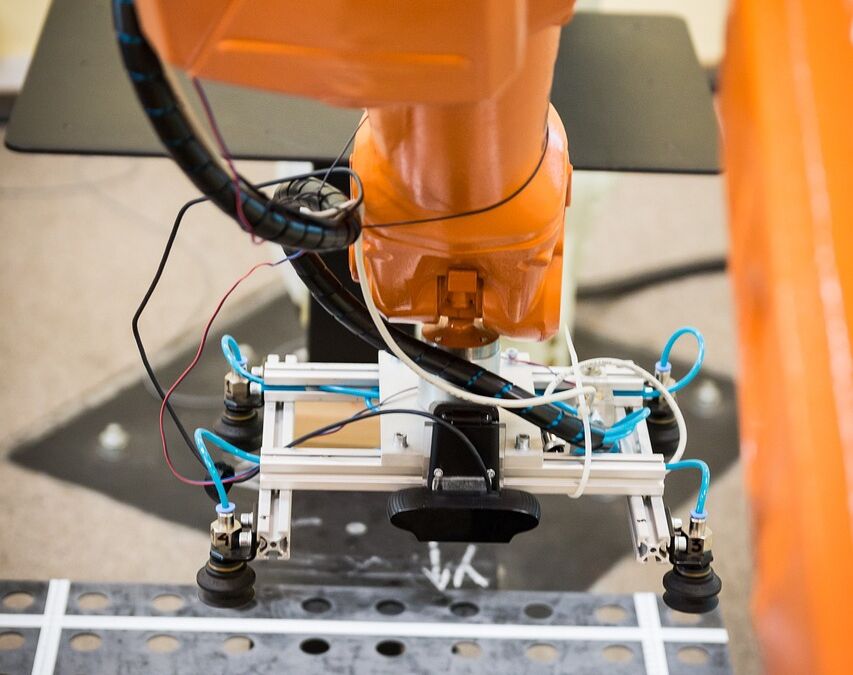

The Power of Automation in PCB and Solder Inspection

Automation plays a pivotal role in PCB and solder inspection, offering numerous advantages:

- Enhanced Efficiency: Automated systems can handle large volumes of inspections at a much faster rate than manual processes.

- Improved Accuracy: Sophisticated algorithms enable automated systems to detect defects that may be missed by human inspectors.

- Reduced Labor Costs: Automation minimizes the need for human labor, reducing operational expenses.

ASC International’s Innovative Technologies

ASC International’s automated inspection technologies set it apart from the competition:

- 3D Solder Paste Inspection (SPI): Utilizes 3D imaging to accurately measure solder paste volume and detect defects.

- Automated Optical Inspection (AOI): Inspects PCBs for defects such as missing components, misalignments, and solder shorts.

- X-ray Inspection: Provides comprehensive analysis of PCBs, revealing internal defects and component integrity.

Future Horizons in PCB and Solder Inspection Automation

The future of PCB and solder inspection automation holds exciting possibilities:

- Machine Learning and AI: Integration of machine learning algorithms will enhance defect detection and improve inspection accuracy.

- 3D Metrology: Advanced 3D metrology techniques will enable more precise measurements and quality control.

- Real-Time Monitoring: Continuous monitoring systems will provide real-time insights into inspection processes, optimizing efficiency and reducing downtime.

ASC International’s Commitment to Innovation

ASC International remains committed to driving innovation in the PCB and solder inspection industry. Through ongoing research and development, ASC continues to provide state-of-the-art solutions that meet the evolving needs of manufacturers.

ASC International’s Automated Inspection Technology Resources for the Waynesboro, PA Area

ASC International’s comprehensive resources support manufacturers in the Waynesboro, PA area. Its local distribution center ensures prompt delivery of inspection systems, while its customer support team provides expert advice and technical assistance. By partnering with ASC International, Waynesboro manufacturers can elevate their PCB and solder inspection processes, ensuring the highest standards of quality and efficiency.

Contact ASC International Today

Enhance your PCB and solder inspection capabilities with ASC International’s cutting-edge technologies. To learn more about their solutions and how they can revolutionize your manufacturing processes, visit https://ascinternational.com or contact their team directly.