ASC International: The Guiding Light in PCB and Solder Inspection Automation

TL;DR

ASC International is a global leader in PCB and solder inspection automation solutions. Their cutting-edge technologies and commitment to innovation empower electronics manufacturers to achieve unparalleled accuracy, efficiency, and quality in their inspection processes.

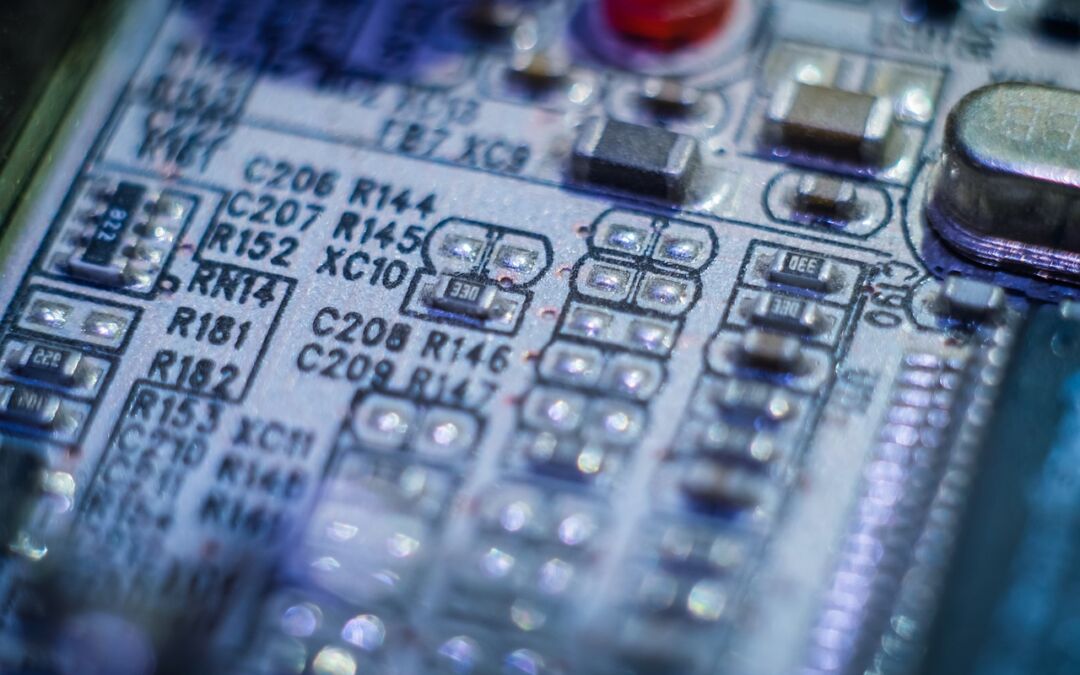

Understanding the PCB and Solder Inspection Landscape

In the electronics industry, PCBs (printed circuit boards) and solder joints play a crucial role. Ensuring their integrity is paramount to guarantee the functionality and reliability of electronic devices. PCB inspection involves examining boards for defects, while solder inspection verifies the quality of solder joints.

ASC International: A Pioneer in Automation

For over 30 years, ASC International has been at the forefront of automating PCB and solder inspection processes. Their automated solutions leverage advanced technologies like Automated Optical Inspection (AOI) and X-ray inspection to deliver exceptional precision and speed.

Key Products and Services

ASC International’s product portfolio includes:

- Automated Optical Inspection (AOI) systems

- X-ray inspection systems

- Solder paste inspection systems

- SPI (Solder Paste Inspection) equipment

- AOI Solder Joint Inspection (SJI) systems

Advancing Inspection Techniques

ASC International’s team of experts continuously pushes the boundaries of inspection technology. Their solutions include:

- 3D AOI systems: Provide comprehensive inspection of complex PCBs and solder joints

- High-speed X-ray inspection: Detect internal defects and analyze solder joint cross-sections

- Intelligent software algorithms: Automatically identify and classify defects, reducing false positives

Benefits of Automation

Automation in PCB and solder inspection offers numerous advantages:

- Increased accuracy: Automated systems eliminate human error, resulting in more precise and reliable inspections.

- Improved efficiency: Automated solutions significantly reduce inspection time, enabling manufacturers to increase production output.

- Enhanced quality control: Continuous monitoring and automated data analysis ensure consistent quality throughout the manufacturing process.

Customer Success Stories

ASC International’s customers attest to the exceptional performance of their solutions. For instance, a leading electronics manufacturer reported a 30% increase in inspection efficiency after implementing ASC International’s AOI system.

Future Innovations

As technology evolves, ASC International remains dedicated to developing innovative solutions. Future developments include:

- Artificial intelligence (AI): Enhancing defect detection capabilities and optimizing inspection parameters.

- Cloud-based inspection: Enabling remote monitoring and data analysis, empowering manufacturers to make informed decisions anywhere, anytime.

- Smart sensors: Collecting real-time data for predictive maintenance and process improvements.

Conclusion

ASC International’s relentless pursuit of innovation has revolutionized the PCB and solder inspection industry. Their automated solutions have become an indispensable tool for electronics manufacturers, delivering unprecedented accuracy, efficiency, and quality. As the industry continues to evolve, ASC International remains steadfast in its commitment to providing cutting-edge solutions that empower manufacturers to stay ahead in the competitive electronics market.